With WORK Microwave’s WORKsens SR series, you can measure the moisture of various materials in a totally contact-free way. The underlying concept of our solution relies on microwave technology to accurately measure the moisture of materials like paper, pulp, cardboard, corrugated cardboard, foils, textiles and other web and board materials.

Contactless Inline Moisture Measurement

Contactless Inline Moisture Measurement of textiles, paper & pulp and many others

WORKsens SR-90 – measuring gap up to 20 mm

The WORKsens SR series is an ideal solution for fast-running roll-to-roll manufacturing. The sensor system can be integrated seamlessly at measuring bridges of production lines, performing measurements with high accuracy and speed. WORKsens SR is designed for robust and maintenance-free application.

The measuring sensors are accessible via TCP/IP interfaces and can be connected via LAN and USB — meaning it is Industry 4.0 ready! Also the integration into existing systems is easy due to industry standard interfaces like a current data line.

Ask us regarding your application:

All Benefits: Contactless Inline Moisture Measurement with WORKsens SR series

WORKsens SR series: Seamless Quality Assurance via Contactless inline moisture measurement

Demanding measurement applications need a technologically appropriate approach. That’s why WORK Microwave has developed high-tech evaluation electronics for any enhanced measurement method.

Our WORKsens SR offers the following advanced feature set:

- Direct Digital Synthesis (DDS) concept in combination with the microwave resonance method

- High accuracy, achieved by a dense frequency resolution

- High update rate – Over 500 measurements per second possible

- 16-bit amplitude resolution for a high dynamic range

Application Area SR-90:

Measurable water content up to 200 g/qm

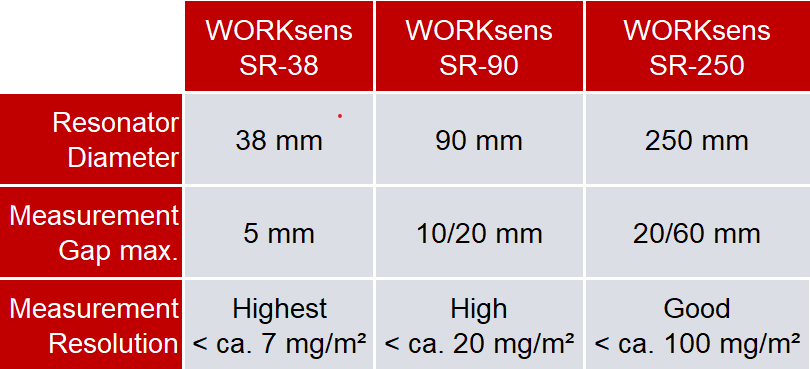

WORKsens SR series at a Glance:

Real-Time Contactless Inline Moisture Measurement Data

The WORKsens SR series has a high speed signal processing unit that analyzes the data directly. Measurement results are fed to any process monitoring and control system in near real time.

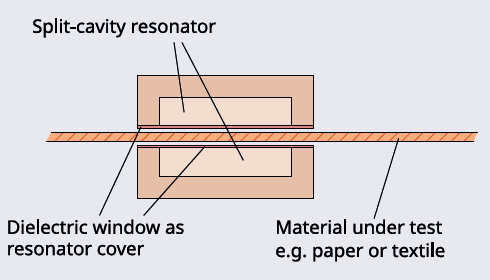

When developing the WORKsens SR series, WORK Microwave chose a resonance method that eliminates disturbances from the outside and enables best-in-class accuracy. Our sensor uniquely characterizes the material under test in an enclosed electromagnetic field.

WORKsens SR series Principle

Mind the Measurement Gap at Inline Moisture Measurement

The WORKsens SR series is optimized to be used on fast-moving production lines. The wide measurement gap ensures an intrusion-free passage of the material.

The resonator’s diameter is scaled to ensure the best and most reliable measurements for your specific application setup. Scaling the diameter affects the operation frequency of the resonator. That frequency is used to adjust the measurement accuracy when characterizing very thin materials. At lower frequencies, thicker materials can also be measured effectively.

Thicker material? See our sensor solutions for measuring gaps of over 1,500 mm:

Quick, Easy Installation and Operation

WORK Microwave delivers the resonator and the electronic module ready to be integrated into the housing of your application. Our team of experts will provide support during the integration phase, if needed. In addition, we can design customized housing solutions for any application.

The WORKsens SR series system will be installed within your production line at a suitable fixed location, or on a moving scanner bridge.

The on-board communication interface of the WORKsens SR series connects seamlessly to any control system and is industry 4.0 ready. For monitoring and calibration settings, you can directly access the sensor via TCP/IP or USB interface.

After a simple calibration process, the sensor is ready to perform measurements 24 hours a day, seven days a week.

If you install the WORKsens SR sensor on a moving measurement bridge, the sensor can compensate height misalignments between the lower and the upper resonator halves which would otherwise lead to measurement errors.