Measurement methodologies using microwave frequencies and RF resonators are considered the most accurate way to obtain measurement data to calculate the weight, humidity, or content of water in a variety of materials.

Advantages of Microwave Frequencies

Today, microwave frequencies up to 100 GHz are increasingly being used in industrial applications. When utilized with a special resonator that adapts to the material, one can reliably obtain electrical data like complex permittivity and complex permeability and, in turn, accurately calculate the weight, humidity, or content of water. Because of the wide range of available microwave frequencies, the measurement method can be customized based on the material. Also, microwave sensors provide an overall ease of use, especially compared with nuclear sensors.

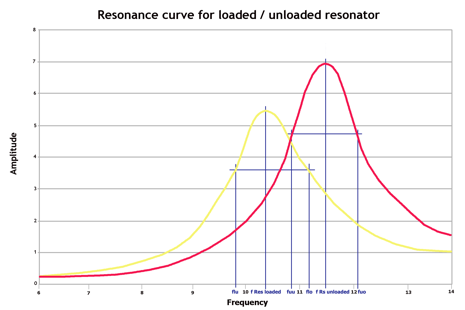

Resonators are high quality factor (Q factor) structures that resonate at certain frequencies. A sample material inside of the cavity region affects the center frequency and Q factor of the cavity. Various resonant techniques are available, but the perturbation method is the most commonly used technique. The electrical data like permittivity and permeability of a material can be determined using the frequency shift between f Res unloaded and f Res loaded. The Q factor is calculated based on the frequencies 3dB down to the magnitude at resonance, in the plot marked as flu/flo and fuu/fuo. When both the shift in resonance frequency and Q factor are measured, one can determine two corresponding physical data, for example, the weight and humidity. In many cases only one physical data is required; therefore, it’s only necessary to measure the shift in resonance frequency or the Q factor, rather than both. A typical measurement system using the resonant cavity method consists of a resonator cavity, a signal processing part, and software control by a computer.

Using high-precision sensors based on the microwave resonator technique, manufacturers can measure the moisture, mass, and density properties of a wide range of materials, in addition to identifying foreign particles or substances that may have come into contact with those materials. This technique has been particularly beneficial for determining the water content of paper during the production process. The ability to control the mixture or composition of water and wood helps to optimize the quality, production throughput, and overall manufacturing costs for paper manufacturers.

Case Study: Measuring Water Content in Paper

One of the most serious issues in paper production is when the material becomes too dry or too wet, because the paper must then be discarded, wasting a manufacturer’s time and money. This can be prevented by controlling the moisture within a production space. Utilizing the high-speed measuring technology of microwave resonance sensors, a paper manufacturer can accurately stay within the ideal moisture range of roughly 4 to 8 percent, thus eliminating the threat of moisture. Sensors can measure the surface as well as the interior of the paper without actually coming into contact with the materials. A moisture sensor also has the capability to measure glue layers applied to paper and the drying of printing inks.

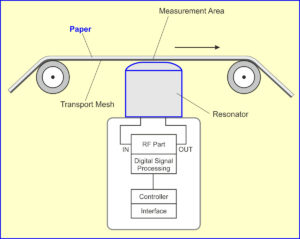

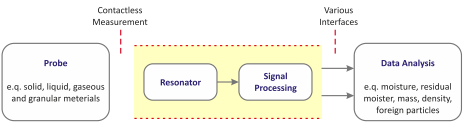

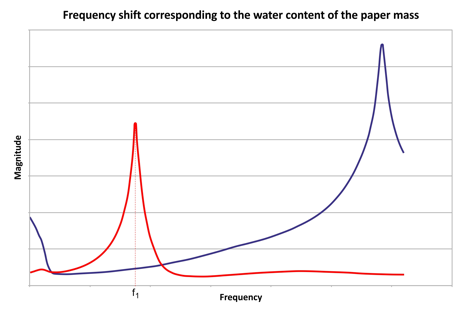

After a microwave sensor is installed, the device performs a contactless measurement of the paper via a probe, which detects any solid, liquid, gaseous, and granular materials, in this case paper. (See Figure 1.) The resonator then determines the water content of the paper. The paper mass/pulp is transported on a mesh carrier, with a sensor installed directly underneath of it. (See Figure 2.) The resulting resonance frequency is measured with a special vectoral network analyzer configuration. (See Figure 3.) Using digital signal processing, a very precise and fast measurement is taken, typically at a speed of up to 10,000 samples per second. The final step in the process is data analysis, which provides the paper manufacturer with measurement results of moisture, residual moisture, mass, density, and foreign particles. The paper manufacturer then evaluates the results to determine if any adjustments to the production process need to be made.

Figure 1. Resonator-based measurement system

Fig 2. Diagram of sensor system with one-sided resonator installation

Figure 3. A vectoral network analyzer measures the resonance frequency (at a speed of up to 10,000 samples per second). The blue curve shows the resonator measurement with no paper (for comparison). The red curve shows the resonator measurement with paper. The peak of the red curve indicates the resonator frequency value, which in this instance is equal to F1. The frequency shift corresponds to the water content of the paper mass.

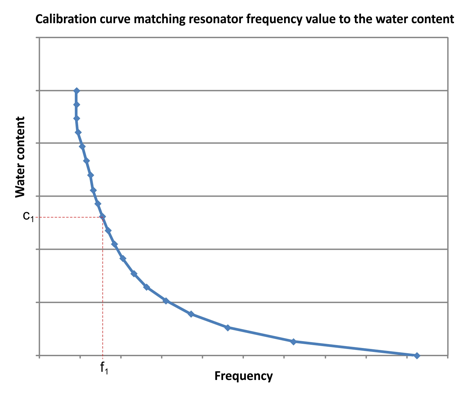

Figure 4. Calibration curve to determine the relationship between the resonator frequency value and the water content.

User Interfaces

Microwave resonator-based sensors like the one used in this application are compatible with a wide range of industry standard communication interfaces, which monitor and control the sensor’s functions. Due to the universal design of the sensor’s data interface, communication interfaces and customized interface boards can easily be added to the sensor for optimal integration of the sensor into a specific environment.

The communication module of the sensor is equipped with a standard IEEE 802.3 Ethernet interface so manufacturers can directly access a sensor’s data through simply setting it up with a computer. The sensor also features support for an ISO 11898-compliant CAN 2.0 interface so that it can be fully integrated within production environments that contain a variety of sensors and actuators.

For rough environments, the sensor includes provisions for a DIN 66258 current loop serial interface.

Utilizing one of these ports, important operating data can easily be read from the sensor, providing a further ease of use for manufacturers

Any calibration formula or measurement table can be implemented into the firmware of the sensor to deliver a direct and accurate reading of the paper’s water content. (See Figure 4.) Using the previously identified frequency value of F1 (from Figure 3), the water content can be traced on the curve to approximately C1. If C1 is above or below the optimum percent for high-quality finished paper, then the paper manufacturer can either stop or increase the water flow on the production line to ensure a constant water percentage which will ultimately produce the optimum quality of paper.

Benefits of RF Resonators

In addition to accurately measuring the fiber content of paper pulp, manufacturers employing a noninvasive, noncontact sensing technology based on microwave resonator technique are provided many additional benefits not offered by other measurement methods.

For example, the resonator technique enables manufacturers to measure a very small sample, as small as 1mm3, with precision accuracy at a rate much faster than alternative systems. This fast measurement of 10,000 samples per second makes it ideal for demanding in-line applications like the paper manufacturing industry.

A microwave resonator method is also capable to characterize low loss materials and materials with a low dielectric constant, which are extremely difficult to measure with other electrical measurement techniques. Substances with a low dielectric constant include a perfect vacuum; dry air; and most pure, dry gases such as helium and nitrogen. Materials with moderate dielectric constants include ceramics, distilled water, paper, mica, polyethylene, and glass. Metal oxides, in general, have high dielectric constants.

Until recently, nuclear-based sensors have been the standard for measuring the water properties in paper. New sensors based on RF technology eliminate the need for handling nuclear sensors, enabling manufacturers to avoid the cost and time involved in specialized nuclear sensor handling and training for employees. Nuclear sensors always contain a certain amount of radioactive material; therefore, manufactures face restrictions when distributing the equipment to certain countries or may have to apply for a special approval to export. These issues can be avoided by using RF-based sensors, which are not affected by those restrictions. Because radioactive waste is harmful to most forms of life and the environment, nuclear-based sensors also require a stringent waste disposal process that is heavily regulated by the government. Using an RF-based sensor, manufacturers can reduce any potential source of environmental contamination while simultaneously lowering energy costs.

The microwave resonator technique also enables manufacturers to use sensors with a flow-through resonator or one-sided resonator measurement. Both systems perform a contactless measurement, meaning the sensor head does not come into contact with the mesh carrier. Sensors with a flow-through resonator are usually used for measuring powders, liquids, granulates, or pallets up to a certain size. The size of the material is the main limitation for the flow-through type of resonators. In applications like paper production, where the width of a piece of paper in the production line can measure up to 6 meters, the use of such a sensor is impossible in most cases, and would be extremely expensive to design and manufacture. In this case, a sensor with one-sided measurement is an appropriate solution. It is also suitable in applications where the thickness of the material in the production process is subject to larger variations. This sensor type can easily be integrated into an existing system.

Conclusion

Using a sensor based on the resonator measurement technique, a paper manufacturer can determine an optimum frequency range for the resonator, thus ensuring with extreme accuracy that the paper maintains a low water content. This ultimately leads to an improved product quality and increased productivity.

Sensors using this technique are flexible enough to maintain both low and high water constants; therefore, this is a cost-effective solution, as manufacturers can employ one sensor for dual purposes. The microwave resonator measurement technique also ensures slow degradation of water content from the paper, which is essential to producing superior paper.

RF sensors based on the microwave resonator technique can also be applied in other industries, such as food, tobacco, pharmaceutical, automotive, recycling, and chemicals, to measure moisture, mass, and density, as well as identify foreign particles and dielectric properties. Because quality assurance is so critical in any manufacturing type of industry, the RF sensor gives companies the peace of mind that their materials meet and exceed quality expectations so that they can deliver the best product to consumers.